We find it necessary to dispel Pull Planning misconceptions as they’ve been marketed and their impact on project planning and schedule maintenance. Principally, published literature attempting to contrast Pull Planning with CPM by advertising Pull Planning leverages upon collaborative feedback and CPM is created in silos is patently false. Are there any project management professionals out there who genuinely believe practitioners of CPM create or maintain schedules in silos without subcontractors’ feedback or that CPM schedulers don’t among other goals seek the project team’s schedule buy-in for project execution? The question is rhetorical.

Some expand Pull Planning misconceptions further in their attempts to sell contractors on their graphical schedule management system as “pull planning driven”. They pitch that discussing the schedule’s current and near-term tasks in the context of lining the job trailer’s walls with whiteboards turned into calendars adorned by annotated multi-colored post-its or utilizing graphical tools to illustrate task sequence strings is Pull Planning schedule management. To us, that’s not Pull Planning, it’s a just subcontractor meeting. Have you ever heard of a weekly subcontractor meeting where the schedule’s tasks and targets were not collaboratively discussed with subcontractors? Neither have we.

More problematically, because neither of the above methods are CPM driven, as project delays mount from various scopes the “Pull Planning wall wizards” and the graphical schedule practitioners have no immediate knowledge for the exact quantification of delay on the project’s longest path at the end of the subcontractor meeting – and in many cases which of the competing delays drives the project’s completion path. Think for example of a vertical construction structure in which the exterior, roofing and wet rough-ins are all ongoing simultaneously but where each experiences its own delays from one schedule update to the next. All have an impact on achieving overhead dry-in and the start of dry rough-ins (duct board and electric pulled wire) that drive the dependent downstream tasks. Without CPM calculation, there’s no immediate indication for the controlling delay path after targets have been obtained at the subcontractor meeting. Discussion aimed to obtain improved subcontractor commitments devoid of CPM calculation is akin to flying at night with no GPS, prompting doubt as to whether the “Pull was full” – or at all effective.

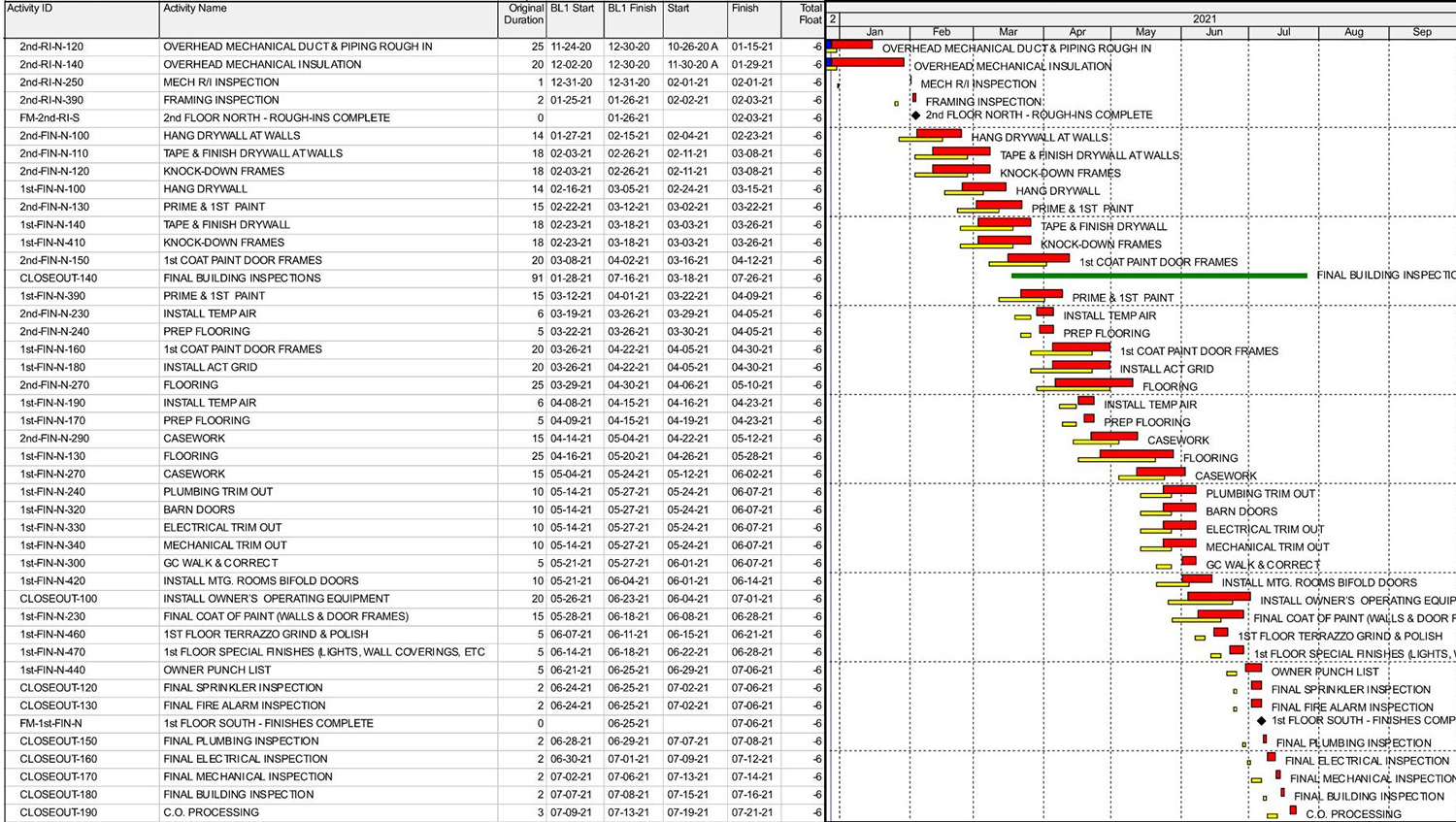

We maintain that “actual Pull Planning” aims to do just what it implies, to pull the end of the schedule back as far as practically achievable. Hence, an actual Pull Planning undertaking requires schedule management in CPM tools and represents the third and final step in our routine schedule maintenance process that unfolds as follows: First, task status is processed into a CPM tool and the schedule is updated to reflect the current commitments obtained at the subcontractor meeting. Second, after the subs have been dismissed, the logic of in-progress tasks is quickly reconciled from the previous as-planned logic to the current as-built logic. Third, the schedule is grouped and sorted to illustrate the project’s multiple completion paths in order of their delay criticality.

Now the real Pull Planning exercise can begin to complete the schedule update. The longest path illustrates the greatest delay with the relevant near-term tasks and responsible subcontractors/issues. Subcontractors on the longest path get called back individually into the job trailer where baseline durations, manpower, working days and work shifts are reviewed to obtain improved completion targets. Once these revised commitments are processed into the schedule’s longest path, the schedule is updated again and either depicts the same or revised controlling longest path. In instances the controlling path changes the process is repeated until the project management team concludes the schedule cannot be practically pulled back further with either improved commitments or resequencing. The outcome achieves a true Pull Planning resultant that reflects precise quantification of delay and the responsible stakeholders and controlling issues. True Pull Planning requires CPM utilization to navigate controlling delays.

How can we help your

project’s success?

Click the button to the right or give us a call

to find out how we can be of service.